1. Awareness

The first and most common mistake made with wire harnessing is simply knowing when to use a wire harness. In many industries, projects can get complicated very quickly, and wire harnessing is a fast, effective way to keep applications organized and increasingly efficient. Being unaware of wire harness capabilities can hurt your organization's effectiveness and production.

Sycor Technology has a long history of helping large and small organizations figure out what the most cost-effective and efficient wire harness would be. The Sycor team also offers in-house assemblies that serve a wide range of industries. Creating, modifying, and correcting wire harnessing designs since 1981, our team is one of the most experienced and knowledgeable harnessing manufacturers in North America and meets your harnessing needs no matter how difficult.

2. The wrong type of harness

Over the years our team has dealt with a variety of harnessing requests that range from extremely detailed to overly simplistic, and one trend that's consistent within these requests is customers ordering the incorrect type of harness. Understanding exactly what your harness requires is extremely important, because even if you completely understand the application, very often old or similar application harnesses won't work.

This issue occurs more than you'd expect, but over the years, our team has come up with a foolproof system that ensures our customer's harnesses are configured accurately with the correct parts. After customers have ordered their harnesses, and sent in their harnessing design and specs, our team creates a single prototype. After creation, the prototype is sent to the customers' desired location for what is called 'First Article Inspection' (FAI). This allows our customers to test everything they need, and if there's an issue, our sales team can work with the customer to figure out where the issue is and if a new wire harness drawing (design) is required. This process ensures customers' orders are correct 100% of the time and can potentially save time and resources.

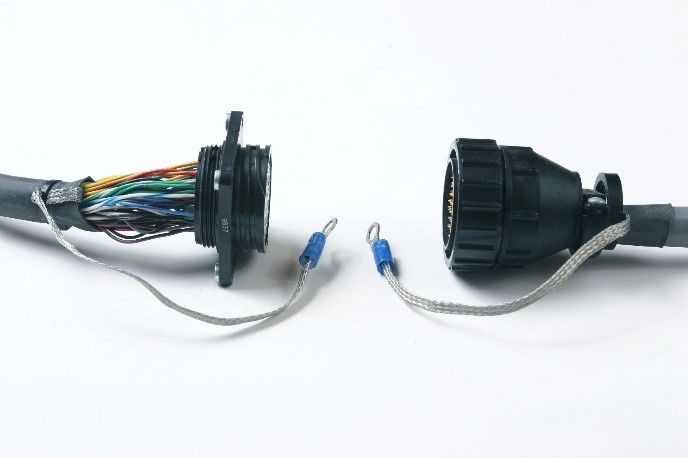

3. Incorrect cable length

When designing a wire harness for construction, there's a wide range of considerations to take into account, and one that's often overlooked is the length of the cable. This often happens when engineers and electrical personnel underestimate the length required. When there isn't enough wire, and your connectors are unable to reach their desired destination, your harness becomes subsequently useless. Our in-house wire harness manufacturers have come across this issue quite frequently, but thanks to our FAI, we were able to catch the issue in the prototype and save customers a great deal of stress, time, and money.

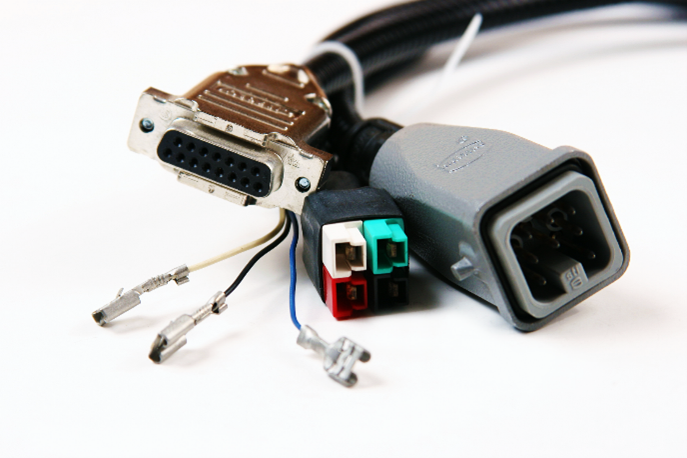

4. The wrong type of connector

Our team is arguably one of the most experienced wire harness manufacturers in North America and has a long history of working with a broad range of clientele, from fledgling to adept, and everything in between. When dealing with a complicated harness, customers will often overlook the simple parts and focus on the more complicated ones. One of these 'simple parts' that we often discover issues with during our customers' FAI is the 'connector types.' The correct connector references a male or female connector, the piece plugging in or being plugged in. When the incorrect connector is used the harness is rendered useless as there's no way to connect it to its intended application. This issue is difficult to predict as human error is the only cause.

5. Damaged Wire

The last major issue that our wire harnessing team comes across is 'damaged wire.' This issue, unlike the others, is unavoidable because 99% of the time it occurs during either shipping or the creation of the product. Thankfully this can be fixed quite easily by contacting the wire manufacturer and explaining the problem, which Sycor would take care of. The major downside to this issue is the delay it causes in the manufacturing process and delivery.

That concludes the 5 most common wire harnessing mistakes! Our team takes pride in providing exceptional products to our customers and we are happy to receive feedback on all our harnessing products. For any further help developing a new wire harnessing product or sub-assembly that requires internal cabling or wire harnesses, put our resources and extensive cabling experience to work for you.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]