There's a wide range of different military-approved wire, but today we're only going to be discussing the two most popular types. The m16878 and m22759 are similar mil-spec wires, some being used for cost-effective general-purpose applications, while others are used in harsh high-temperature environments. These cables are some of the most important in terms of consistent performance, because of their roles within applications, which is why QPL was adopted.

Mil-Spec QPL:

Qualified Product Listing

- One of the most important aspects of military wiring is QPL. QPL stands for "Qualified Product Listing," which is basically a list that shows both the materials and the different suppliers who are approved for use in certain federal government projects.

- On a QPL, certain manufacturers have been approved to make specific parts for federal aerospace or military applications, because they have proven they can reproduce the standard products to their exact requirements.

- Mil-spec wires that are listed under QPL are labeled as "QPL Approved," which is done to help government and private institutions immediately identify which products are qualified for specific applications.

- A QPL approval can only be obtained by a company that submits a sample product to be tested against the requirements by an approved testing agency. This is also all done before the final purchase to ensure the product qualification is delivered without delay.

- QPL overall is used for very specific federal applications and has been put in place in order to provide the safest outcome possible, as many applications can be extremely dangerous for certain personnel (Military, Aerospace, etc.).

Mil-W-16878, M16878 Breakdown

The Mil-W-16878 are reliable cables that are often used as UL and CSA alternatives. As an alternative, the m16878 is able to be used in applications that are much more demanding. Being used for general purpose or military applications enables these multi-purpose cables to be used in a wide range of different environments. The m16878 configurations are very durable military cables. They are manufactured using the highest quality materials such as nickel-plated conductors, silver-plated conductors, as well as tinned copper and bare copper conductors. Having quality materials is essential for supplying products that are able to withstand harsh environments and constant maintenance reliably.

M16878 Construction Variations

The construction of the M16878 is very similar to the UL/CSA approved hook-up wire but is typically either approved for a higher-voltage or is constructed with thinner insulation (for greater flexibility). The M16878 constructions also have a few very unique attributes that include outer glass braids, double wrapped Teflon insulations, and even double wrapped Teflon insulation with an outer glass braid.

M16878 Approvals

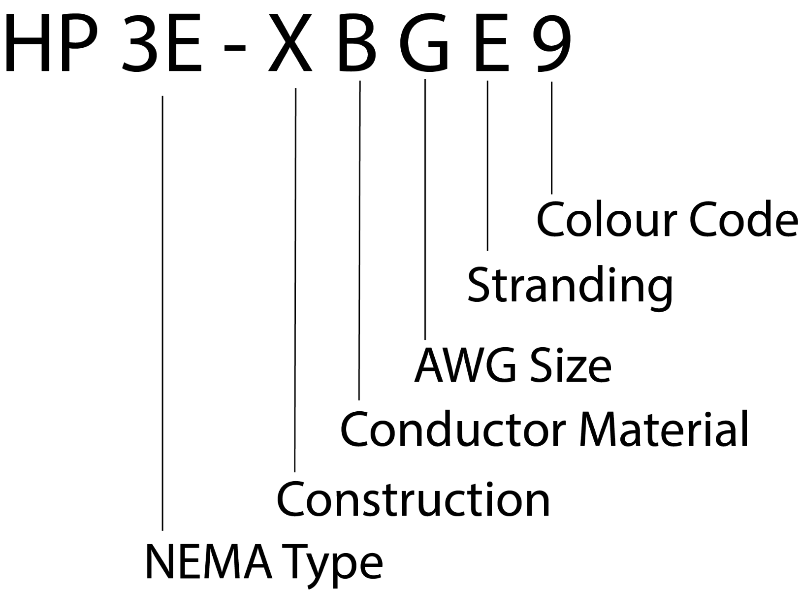

NEMA HP3 – HP8 are the new m16878 wiring designations and are used to identify different constructions, although most industries still use the traditional "16878". The last unique aspect that the m16878 has is how the conductor plating, gauge and stranding are identified. The m16878 cables use three letters at the end of the slant (m16878/5BBA). Each letter is then used to identify a different aspect of the cable. This style became popular because it enables electrical personnel and purchasers to immediately identify the standing and gauge size without an additional reference sheet.

M16878 Applications

Similar to the m22759, the m16878 comes in various constructions, each of which is able to provide different strengths to the intended applications. With a voltage rating ranging from 300 Volts to 5000 Volts, the m16878 cable is rated for low and high voltage applications within the military, government, and aerospace markets, but can also be used for some commercial applications when required.

M16878 Constructions Popular Among Customers

The first nine constructions are typically used as a cost-effective hook-up wire alternative, for any applications that don't require any CSA/UL approval.

|

Slant Number |

Type |

Conductor |

Voltage |

Temp. |

Insulation |

Mil-W or Mil-DTL |

NEMA Type |

|

B |

Tin or Silver |

600V |

105ºC |

PVC |

Mil-DTL, Mil-W |

NEMA HP-7 |

|

|

B |

Tin or Silver |

600V |

105ºC |

XLPVC |

Mil-DTL, Mil-W |

NEMA HP-7 |

|

|

C |

Tin or Silver |

1000V |

105ºC |

PVC |

Mil-DTL, Mil-W |

NEMA HP-7 |

|

|

D |

Tin or Silver |

3000V |

105ºC |

PVC |

Mil-DTL, Mil-W |

NEMA HP-7 |

|

|

E |

Silver |

600V |

200ºC |

PTFE |

Mil-W |

NEMA HP-3 |

|

|

EE |

Silver |

1000V |

200ºC |

PTFE |

Mil-W |

NEMA HP-3 |

|

|

ET |

Silver |

250V |

200ºC |

PTFE |

Mil-W |

NEMA HP-3 |

|

|

F |

Silver |

600V |

200ºC |

Silicone Rubber |

Mil-DTL |

NEMA HP-6 |

|

|

FF |

Silver |

1000V |

200ºC |

Silicone Rubber |

Mil-DTL |

NEMA HP-6 |

|

|

|

|

|

|

|

|

Mil-W-22759, M22759 Breakdown & Applications

The major difference between the m22759 and m16878 is the 22759 has a more extensive selection of fluoropolymer insulation constructions, because of the applications the 22759 cables are subject too. Mil-W-22759 (m22759) or SAE AS22759 is constantly relied on for military, aerospace and defence agency applications. The m22759 is designed for high-performance and meets the requirements for low weight, high-temperature resistance, low flame and small dimension installations.

M22759 Construction Variations

The m22759 cables are rated for higher voltage ratings and are created for the most demanding military and aerospace applications. The m22759 are often subject to constant QPL testing because of their high-demand within critical applications (Aircrafts, Military). Over the years, different constructions have been created, discontinued and improved. This consistently happens as more reliable constructions at more cost-effective prices are constantly in development.

The m22759 being a single conductor electrical wire, has variations in constructions like the tin, nickel or silver-plated copper conductors. The different conductor constructions enable the m22759 wire to be used in varying temperatures and environments. The final significant difference between the varying m22759 models are the different insulations. Some of these insulations are polyvinylidene fluoride (PVF2), polytetrafluoroethylene (TFE), fluorinated ethylene propylene (FEP) and ethylene-tetrafluoroethylene copolymer (ETFE).

Overall the M16878 and M22759 mil-spec wires are similar, but at the same time are very different. Have a question about Mil-Spec wires? Not sure which Mil-Spec wire or cable is right for your specific application? Curious about wires in general? We have the answers. Sycor’s highly knowledgeable team is at your disposal. Request a quote online, email, or call us today!

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]