Mil-Spec Wire

Sycor’s mil-spec wire is typically used in demanding military applications, where reliability is essential. These products are relied on for difficult and demanding applications, because of how they’re able to handle high-frequency applications, which more than likely will be subject to extreme temperatures and harsh environments. These types of applications range from point-to-point wiring, antennas, bonding moving parts, airframe wiring, and where durable shielding is required.

Over the years many different standards have been used to separate the different attributes that each wire offers. There is a wide variety of different types of mil-spec wire such as:

- M16878

- M22759

- M13486

- M5086

- M3432

- M27500

- Mil-C-17

- M13486

Sycor's largest Mil-Spec categories are the Mil-W-22759 (m22759) & Mil-W-16878 (m16878) designations. The m16878 and m22759 wires follow the same trend as all other mil-spec products and are specific for every product with a different slant. These slants are important to note because although they may be able to serve similar applications, each slant's construction will change slightly.

Sycor Technology has added two easy-to-navigate areas on our new website in order to help experienced customers find what they need quickly, and inexperienced customers better understand the differences between the products (slants)

2 Customer-Friendly Mil-Spec Additions:

- For experienced customers, we've added the "Mil-Spec Quick Navigation" page. This page is updated continuously with every military wire that Sycor Stocks in an extremely organized fashion.

- The second new addition is aimed at more inexperienced mil-spec wire personnel. This new addition breaks each cable down by its core components: conductor plating, voltage, temperature, type, insulation and even the NEMA designation. This enables new wire and cable purchasers to see each slants construction and capabilities in a single, easy-to-read style.

M22759, Mil-W-22759 Navigation

|

Mil-Spec Number |

M27500 |

Conductor Plating |

Voltage |

Temp. |

Insulation |

|

EA |

Silver |

600V |

200ºC |

PTFE and PTFE Coated Glass |

|

|

E |

Nickel |

600V |

260ºC |

PTFE and PTFE Coated Glass |

|

|

RA |

Nickel |

600V |

260ºC |

TFE Glass TFE |

|

|

RB |

Silver |

600V |

200ºC |

TFE-Glass-FEP |

|

|

VA |

Silver |

600V |

200ºC |

Abrasion Resistant Mineral Filled TFE |

|

|

WA |

Nickel |

600V |

260ºC |

Abrasion Resistant Mineral Filled TFE |

|

|

SA |

Silver |

600V |

200ºC |

Abrasion Resistant Mineral Filled TFE |

|

|

TA |

Nickel |

600V |

260ºC |

Abrasion Resistant Mineral Filled TFE |

|

|

LE |

Silver |

1000V |

200ºC |

Extruded TFE |

|

|

LH |

Nickel |

1000V |

260ºC |

Extruded TFE |

|

|

RC |

Silver |

600V |

200ºC |

Extruded TFE |

|

|

RE |

Nickel |

600V |

260ºC |

Extruded TFE |

|

|

CA |

Tin |

600V |

135ºC |

FEP-PVF2 |

|

|

CB |

Tin |

600V |

135ºC |

FEP-PVF2 |

|

|

CC |

SPHSCA |

600V |

135ºC |

FEP-PVF2 |

|

|

TE |

Tin |

600V |

150ºC |

Extruded ETFE |

|

|

TF |

SPHSCA |

600V |

150ºC |

Extruded ETFE |

|

|

TG |

Tin |

600V |

150ºC |

Extruded ETFE |

|

|

TH |

SPHSCA |

600V |

150ºC |

Extruded ETFE |

|

|

TK |

SPHSCA |

1000V |

200ºC |

Extruded TFE |

|

|

TL |

NPHSCA |

1000V |

260ºC |

Extruded TFE |

|

|

TM |

SPHSCA |

600V |

200ºC |

Extruded TFE |

|

|

TN |

NPHSCA |

600V |

260ºC |

Extruded TFE |

|

|

JB |

Silver |

600V |

200ºC |

Extruded TFE with Polyimide Coating |

|

|

JC |

Nickel |

600V |

260ºC |

Extruded TFE with Polyimide Coating |

|

|

JD |

SPHSCA |

600V |

200ºC |

Extruded TFE with Polyimide Coating |

|

|

JE |

NPHSCA |

600V |

260ºC |

Extruded TFE with Polyimide Coating |

|

|

SB |

Tin |

600V |

150ºC |

Crosslinked Modified ETFE |

|

|

SC |

SPHSCA |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SD |

Tin |

600V |

150ºC |

Crosslinked Modified ETFE |

|

|

SE |

SPHSCA |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SM |

Nickel |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SN |

NPHSCA |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SP |

Silver |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SR |

Silver |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

SS |

Nickel |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

ST |

NPHSCA |

600V |

200ºC |

Crosslinked Modified ETFE |

|

|

WB |

Tin |

600V |

150ºC |

PTFE/Polyimide |

|

|

WC |

Silver |

600V |

200ºC |

PTFE/Polyimide |

|

|

WE |

NPHSCA |

600V |

260ºC |

PTFE/Polyimide |

|

|

WF |

Silver |

600V |

200ºC |

PTFE/Polyimide |

|

|

WG |

Nickel |

600V |

260ºC |

PTFE/Polyimide |

|

|

WH |

Tin |

600V |

150ºC |

PTFE/Polyimide |

|

|

WJ |

Silver |

600V |

200ºC |

PTFE/Polyimide |

|

|

WK |

Nickel |

600V |

260ºC |

PTFE/Polyimide |

|

|

WL |

Tin |

600V |

150ºC |

PTFE/Polyimide |

|

|

WM |

SPHSCA |

600V |

200ºC |

PTFE/Polyimide |

|

|

WN |

NPHSCA |

600V |

260ºC |

PTFE/Polyimide |

|

|

WP |

Silver |

600V |

200ºC |

PTFE/Polyimide |

|

|

WR |

Nickel |

600V |

260ºC |

PTFE/Polyimide |

Mil-Spec: Mil-W-22759 (M22759)

The designated military wire m22759 or SAE AS22759 is constantly relied on for military, aerospace, and defense agency applications. The m22759 is designed for high-performance applications and meets the requirements for low weight, high-temperature resistance, low flame, and small dimensions. As a single conductor hook-up wire, the m22759 wire and cables are manufactured with tin, nickel or silver-plated copper conductors. The different conductor constructions enable the m22759 to be used in varying temperatures and environments. The final major difference between the m22759 models is the different insulations. Some available insulations for mil-spec wire are polyvinylidene fluoride (PVF2), polytetrafluoroethylene (TFE), fluorinated ethylene propylene (FEP) and ethylene-tetrafluoroethylene copolymer (ETFE). Each insulation provides various strengths towards the intended applications and, in some cases, is combined to create up to 4 separate layers. These unique constructions help provide excellent protection and increased shelf life for various applications that m22759 mil-spec wire may be subject to.

Military wire and cable must be built in accordance with military specifications. The M22759 specification is important to note because these wires are consistently subject to extreme conditions, where weaker cables would fail consistently. The M22759 is a reliable wiring category and is perfect for government or commercial applications requiring extreme resistance.

Mil-Spec: MIL-W-16878 (M16878)

The MIL-W-16878 (m16878) specification identifies the temperature range as -65°C to +250°C. The m16878 is also a designated hook-up wire that's used for high-performance applications that require small dimensions, low weight, high-temperature resistance and low flame.

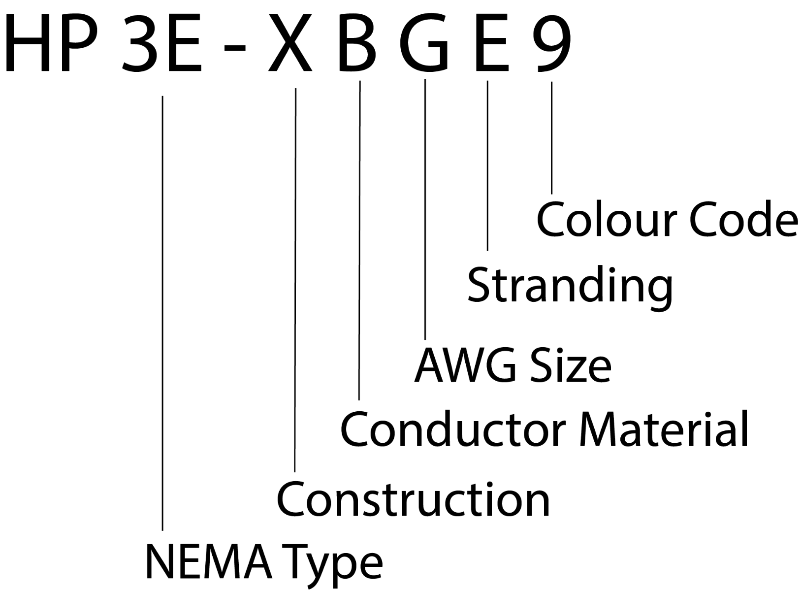

The M16878, similar to its M22759 counterpart, comes in various constructions, each of which gives different strengths to the intended applications. With a voltage rating ranging from 300 Volts to 5000 Volts, the M16878 cable is rated for low and high voltage applications. Typically this cable is used for military, government, and aerospace applications but can be used for some commercial applications when required. NEMA HP3 – HP8 is an m16878 designation and is used to identify different constructions, but most industries still to this day use the traditional "16878".

The final unique aspect that the m16878 cable has is how the conductor plating, gauge, and stranding are identified. While most organizations use the last few numbers at the end of the product code to identify these attributes, this unique product uses three different letters to identify those previously mentioned cable attributes. The unique lettering helps purchasing personnel and engineers find their exact product quickly and efficiently.

Mil-Spec Wire & Cable Brochure

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]