History of Power Cables

The first power distribution system was developed in 1882 by Thomas Edison himself. This system was created in New York City and used copper rods, wrapped in jute, which was then placed in rigid pipes filled with bituminous compound. Vulcanized rubber was discovered earlier by Charles Goodyear in 1844 but was not utilized as an electrical insulation until the 1880s. These rubber-insulated power cables were utilized for 11kv or 11,000-volt circuits in the late 1890s for a project that was known as the Niagara Falls Power Project. This was the beginning of the power cable, although these first-generation prototypes are nothing like the versatile, durable cables that are consistently used today.

Power Cable Constructions

Modern-day cables typically come in a variety of sizes, materials, and types, each of which is used for specific a purpose. Large single-insulated conductors are also sometimes called power cables in the industry. These cables consist of 3 main components: conductors, insulation, and a protective jacket. Three main factors determine the construction and material:

- Working voltage, determining the thickness of the insulation

- Current-carrying capacity, determining the cross-sectional size of the conductor(s)

- Environmental conditions such as temperature, water, chemical or sunlight exposure, and mechanical impact determine the form and composition of the outer cable jacket

Power Cable Construction Limitation

One of the power cable's most notable strengths is its extraordinary resistance against water, chemicals, oils, and the weather. Cabling categories like hook-up wire or mil-spec wire are designed to be very resistant to varying voltage levels and temperature ratings but are quite weak when other forms of outside abuse become part of the application. If hook-up wires are subject to water or the weather within their applications, they'll often be replaced with an alternative that has the capabilities to deal with that application's difficult terrain. The last notable limitation of power cables is the temperature ratings. When handling difficult applications, power cables are limited by their jacketing and insulation material types, only being able to withstand 105°C.

|

|

Power Cable Applications

The power cable is a versatile product that's frequently used because of the wide variety of constructions available. The Sycor team typically stocks 26 different constructions, each providing different benefits than the previous. With various constructions available, the oil-resistant and water-resistant capabilities are the most popular characteristics as they are a requirement of a large majority of the constructions.

Some of these applications include:

- Heavy tools

- Portable stage lights

- Garages

- Battery chargers

- Flexing applications

- When oil and chemicals are present

- Production lines

- Manufacturing facilities

- Within process industries

Portable & Power Cable Lettering

- S = Extra hard service (rated for 600V)

- J = Junior (hard) service (rated for 300V)

- V = Vacuum cord (rated for 300V)

- P = Parallel cord

- E = Elastomer jacket (UL or NEC only)

- T = Thermoplastic jacket

- O = Oil resistant outer jacket

- OO = Oil-resistant outer jacket and inner insulation

- W = Weather and water-resistant - outdoor rated (note: this is NOT the same as Type W, another kind of portable cord)

Power Cables Organized

Thermoplastic Jacket:

STW, STOW, STOOW, SJTW, SJTOW, SJTOOW

Thermoplastic Elastomer Jacket (TPE):

SEOW, SEOOW, SJEOW, SJEOOW

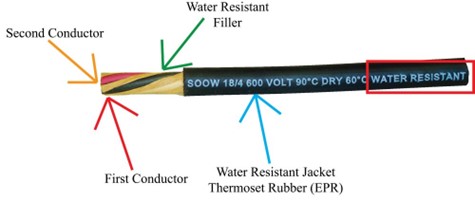

Thermoset Rubber (EPR):

SO, SOO, SOW, SOOW, SJ, SJO, SJOO, SJOW, SJOOW

Vacuum Cord:

SV, SVT, SVO

Power Cable Voltage Ratings

Power cables are unique when it comes to voltage ratings, as the name itself has the rating in it. The extra hard service simply has an "S" with no "J" beside it. This type of cable is rated for the standard 600-volt applications. When the "S" and the "J" are beside one another, it's a 300-volt construction. The voltage ratings are higher for specific construction models like the various DLO cables or the jumper cables, but most of the standard constructions fall between 300-600 volts. Lastly, another unique feature is almost every 600-volt hard service power cable will have an accompanying junior 300-volt construction, so no matter what voltage rating you need, the power cable will have a reliable solution.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]