Every wiring category has a different way of identifying the cable. For example, the power cable uses an assortment of letters, multi-conductors describe the construction, and cable management products use the type of material. Hook-up wires are no different and have a much wider range of constructions than many other categories. These different products are identified by different UL and CSA certifications, which Sycor will break down.

CSA Hook-Up Wire!

Most hook-up wires are identified by specific designations like the common CSA and UL. These designations may represent the same type of product, but they do not have the same meaning. CSA designations for hook-up wire includes the popular CSA REW, CSA TEW, CSA SEW, and even the Type SIS. These unique designations were set in place by the Canadian Standards Association. The CSA is also responsible for additional approvals that are typically directly linked to the application, either by the application itself or the location of the application. Some of these can include CSA FT-4 or CSA AWM.

|

|

|

CSA hook-up wires also have very similar names like TEW, SEW, and REW, with each letter representing something completely different.

REW = Raidiated Equipment Wire

TEW = Thermoplastic Equipment Wire

SEW = Silicone Equipment Wire

UL Hook-Up Wire

UL and CSA have approvals in every hook-up wire, although the UL will often be rated for specific gauge sizes, while the CSA has one rating for all gauge sizes of that construction. The UL certification also typically has the same voltage rating for its products, but if not, it's traditionally lower. UL electrical wiring designations differ a little bit in comparison to CSA because of the variety of different countries that use the UL designations. UL is an overall very popular designation that's almost identical to CSA but can be rated for lower voltage applications.

Mil-Spec Alternatives!

An unknown fact about mil-spec wiring products is that many of them are very similar in construction to hook-up wires. These similar constructions can act as an alternative if the CSA or UL constructions aren't available. These alternatives are identical in specs, with the one differing factor being the product certifications, which means the mil-spec or hook-up wires aren't legally certified for certain application settings.

Mil-spec wire and cable are subject to significantly looser standards than the traditional CSA or UL certifications. The main distinction in these certifications is the application location and the difference in voltage ratings. The standard hook-up wire will almost never go above 600 volts for safety purposes, while the mil-spec alternative is certified for significantly higher. The mil-spec voltages can sometimes be as much as 5x higher than the hook-up wiring counterpart.

*Below are the different CSA/UL hook-up wires, with the mil-spec alternative and the different voltage ratings.

|

Hook-Up Wire |

Alternative Mil-Spec |

Hook-Up Voltage Rating |

Mil-Spec Voltage Rating |

|

600V |

3000V |

||

|

600V |

3000V |

||

|

300V |

1000V |

||

|

300V |

1000V |

||

|

150V |

600V |

||

|

600V |

Not Specified |

||

|

300V |

1000V |

*Products above are CSA/UL & Mil-Spec Alternatives

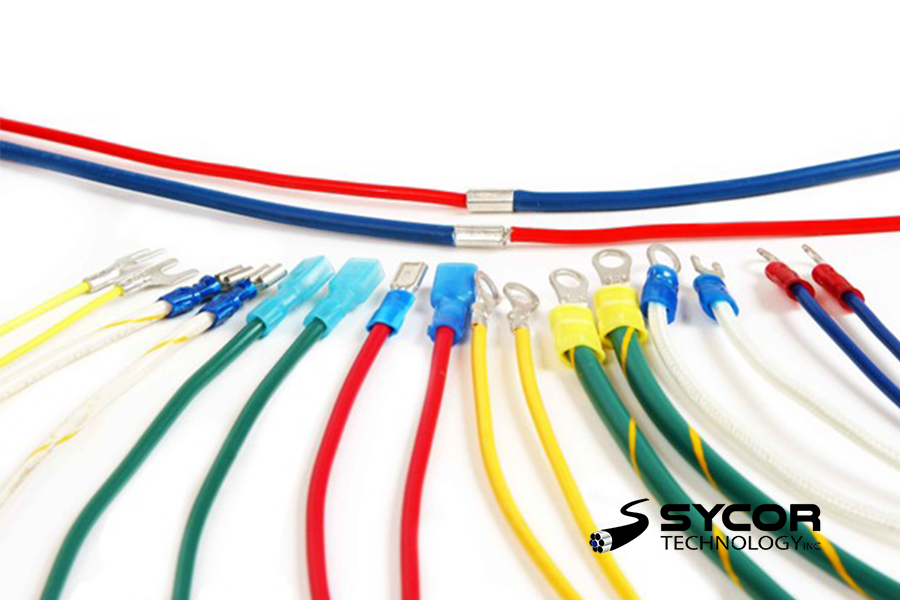

Some of Sycor's most popular hook-up wiring products include:

- CSA TR64 UL1007

- CSA TEW UL1015, UL1028

- Type SIS

- CSA AWM UL10086

Like many other popular wiring products, there are also Belden hook-up wiring alternatives. It's often a misconception that Belden produces a higher quality product, but in reality, the constructions are identical, and rated for the same things, and Belden is almost always priced higher. The Sycor team will always recommend avoiding Belden unless specifically required, as there's no noticeable benefit except for using the brand.

|

Voltage |

Temperature Rating |

Type of Hook-Up Wire |

|

300V |

80°C |

PVC |

|

90°C |

Neoprene |

|

|

105°C |

Cholrosufonated Polyethylene (CSPE) |

|

|

XL-DUR |

||

|

200°C |

TFE |

|

|

600V |

80°C |

Direct Burial |

|

90°C |

Neoprene |

|

|

SIS |

||

|

105°C |

CSPE |

|

|

PPO |

||

|

PVC |

||

|

125°C |

EPDM |

|

|

XL-DUR |

||

|

150°C |

EPDM |

|

|

Silicone Rubber, Braidless |

||

|

Silicone Rubber, Glass Braid |

||

|

Silicone Rubber, Mercury Switch Wire |

||

|

XL-DUR |

||

|

200°C |

Silicone Rubber, Braidless |

|

|

Silicone Rubber, Glass Braid |

||

|

1,000V |

80°C |

PVC |

|

5,000V |

105°C |

CSPE |

|

7,500V |

150°C |

EPDM |

|

17,000 - 40,000V |

80°C |

High Voltage Leads |

The last area to touch on is the high-temperature hook-up wire. This set of products is typically insulated with either the popular Teflon insulation (PTFE, ETFE) or the more flexible Silicone. These insulations come in multiple configurations and have the ability to operate in temperatures that can reach 200°C+ and sometimes even higher. These applications aren't nearly as frequent but typically require larger gauge sizes and high voltage levels. Many high-temperature lead wires that Sycor carries go as large as a 4/0, while the more standard configurations typically won't exceed 8 AWG. The last major difference between standard hook-up wire and high-temperature hook-up wire is the voltages. PVC and XLPE insulated hook-up wires will have one voltage rating, while configurations designed to operate in the heat will often have 2 options. The 300 volts for the smaller gauges and the larger ones being rated for 600 volts.

|

One construction this isn't consistent with is the different SEW configurations. There is four different SEW configurations each differentiating from the other by flexibility and by Voltage Rating. SEW-1 = Less Flexible - 300V SEW-2 = Less Flexible - 600V SEWF-1 = Flexible - 300V SEWF-2 = Flexible - 600V |

|

Hook-up wire is one of the most popular cabling categories used around the world. With applications like internal wiring of electrical equipment, leads of transformers, and motors, these simple constructions are perfect for a number of different applications. These smaller gauged, cost-effective products are also one of the most versatile, flexible, and resistant. Whether your application is simple or extremely detailed, these multi-purpose wires have a construction for whatever solution your team may require.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]