What is Wire Bundling?

Value-Added Service Cutting Example

A good VAS example is Cutting

This value-added service is when customers request to have their cables cut before delivery for a small extra charge. Now what people often forget is these services are designed to save more for the customers. Yes, there's a small extra charge, but is it most cost-effective to have a powerful machine cut tens of thousands of meters of wire in a couple of hours to the exact length required, or is it better to have one of your skilled labourers stand there with scissors and cut it.

- This will cost more.

- May create human error.

- It will more than likely cause some material to be wasted.

- You’ll have to pay your labourer for the extra time.

|

Non-Bundling |

Bundling |

|

|

Wire Bundling Breakdown

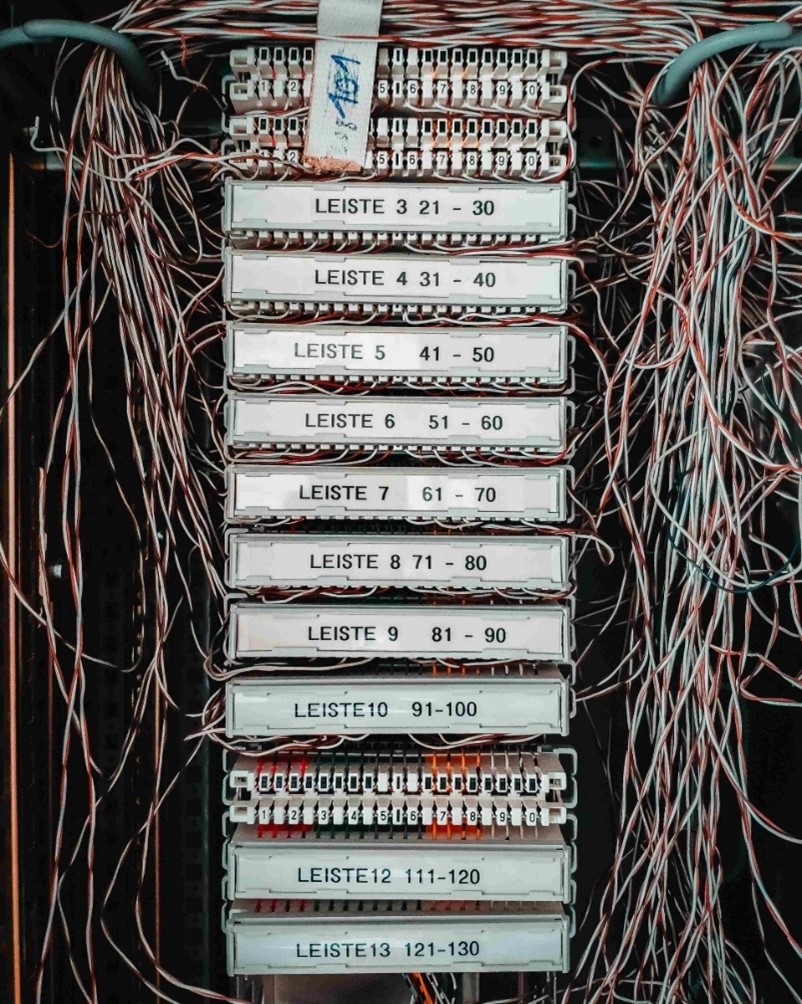

Bundling is a similar service in the sense that it saves on time, labour, and cost. Wire bundling is when you take 2 or more electrical cables and bundle them together using a specific bind. The purpose of the bundling is to keep specific cables together over a medium to long distance. What this does is efficiently organizes those cables in a way that simplifies your application. With various constructions available as well as custom binding requests, wire bundling can effectively help a wide variety of difficult applications.

Different types of Wire Bundling

Straight Wire Bundle

The straight wire bundle has all of its wires tied beside one another rather than twisted. The bundle is typically kept together from Point A to Point B, having little to no breakouts. The straight wire bundling configuration is typically laid in trays and can be installed quite easily. The straight wire bundle isn't as flexible as other configurations, but is easily customizable and keeps workplaces consistently organized during maintenance. The straight wire bundle is one of the more popular configurations because of the benefits it offers, the applications it's used within, and because we offer custom printing and striping for increased organization.

Straight Wire Bundling Benefits:

- The straight bundling configuration helps with heat distribution and minimizes the risks that accompany it. This is a consistent issue with the tightly wound spiral wire bundling configuration.

- The straight wire bundle must be placed not pulled into place (wire ways, gutters, or raceways).

- It provides a more organized and efficient wiring layout.

- It makes maintenance easier and saves time/labour.

Straight Wire Bundling Applications:

- Generators

- Power Plants

- Waste Facilities

- Building HVAC Systems

- Hospitals

- LED Lighting Systems

Overall the straight wire bundling configuration is a strong choice when large quantities of wire are all being placed next to one another. This configuration is also the most reliable and simple but still requires exact length measurements before ordering.

Staggered Wire Bundling

When it comes to bundling wire, each configuration has specific attributes that make it more beneficial for a certain set of applications. The same can be said for the staggered wire bundling configuration. The staggered wire bundle is very similar to the straight bundling construction, as all wires are laid straight and beside one another. What makes this bundle unique is that the main bundle is made up of smaller bundles, and at the desired length, the smaller bundles can break off. This makes breakouts and installing the wiring in multiple systems much more efficient and space-conscious.

Cables used in Staggered Wire Bundling:

- Electronic

- Coax Cable

- Fiber Optic

- Building Wire

- Data Cables

- RW90

- T90

- Hook-Up Wire

- Tray Cable

- And Many More!

The Staggered Wire Bundling Applications:

- Solar Panels

- Construction

- Security Systems

- Conveyor Systems

- Hospitals

- LED Lighting Systems

Overall the staggered wire bundle is a unique construction that, if planned for properly, can help applications tremendously. Being able to break out at multiple points helps customers complete multiple wiring applications, as different types of cable can break away when required. Being able to have building wire, lighting wire, data cable and any other type of cabling group bundled together saves a tremendous amount of space and time. Staggered wire bundling is one of the most challenging configurations to order, but is also the configuration that benefits the most from the added simplicity that bundling provides.

Spiral Wire Bundling

The spiral wire bundle is similar to the straight bundle configuration but has a few unique qualities, the most noticeable being that the bundle has the cables tied together and twisted tightly. Opting for this type of bundling has two distinct advantages.

- The tight twisting helps stop EMI (Electro-Magnetic Interference). This is typically why the spiral bundle is preferred over other constructions in data centers and communication systems.

- Spiral wire bundling offers the ability to be pulled through a conduit. Unlike other constructions (straight and staggered) that have to be laid in conduits or trays, the spiral wire bundle can be pulled through and make up to 90° turns.

Spiral Wire Bundling Benefits

- Used for long pulls through conduits.

- Most space-conscious designs provide increased flexibility.

- The spiral wire bundle helps stop EMI in electronic and data applications.

- Has increased flexibility.

Additional Spiral Wire Bundling Applications:

- Data & Communication Systems

- Industrial Robotics & Automation

- Wind & Solar Farms

- Conveyor Belt System

- Hospitals

- Control Systems

Cables Used In Spiral Bundling:

- Electronic

- Coax Cable

- Fiber Optic

- Building Wire

- Data Cables

- Tray Cable

- And Many More!

Overall the spiral wire bundle is a unique construction that’s perfect for any type of data or communication application. Having the ability to be pulled through instead of laid down, enables the spiral bundles to be used in very tight difficult-to-reach locations. The spiral wire bundling configuration is very reliable and is one of the most popular among general and transmission applications.

Each bundling configuration is unique and useful in its own way. Sycor Technology offers a selection of different value-added services, but bundling is not only one of the most popular but also one of the services that give a very good ROI. Sycor’s highly knowledgeable and experienced sales team would be more than happy to assist you with any of your wire bundling inquiries or questions you may have. Request a quote online, email, or call us today!

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]