ICON legend

Sycor's Wire & Cable Value Added Services

Value Added Services We Offer

|

Custom Re-Spooling All types of wire and cable can be re-spooled into exactly desired lengths. This enables the dispersal of one wire or cable style to a number of different plant/job locations and reduces excess weight and costly inventories. |

|||||||||||||

|

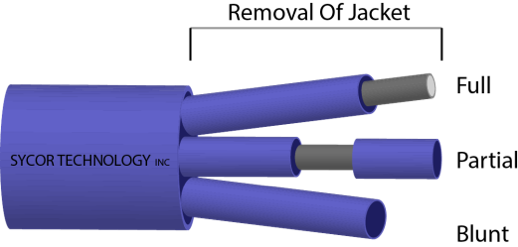

Cutting and Stripping

Sycor is your one-stop solution for all your wire and cable cutting needs. Whether the pieces are 1” or 144”, we can save your time and money. Our facility is equipped with state of the art cutting equipment. Cut lengths can be hot tin-dipped, specially packaged to provide you with the exact material you need, and ready to use for all of your wiring purposes. More Information: To request a quotation,

Blunt: clean-cut – straight Partial Strip: insulation is cut to expose the length required, but not removed thereby protecting the exposed end until ready to use Full Strip: insulation is removed exposing the required length of conductor – ready to use ROJ: for multi-conductor cable, the outer jacket can be removed to expose the inner conductors. The inner conductors can then be blunt, partial or fully stripped per requirements. You can request a quote online, email us or give us a call. Our sales representatives are available if you have any questions about sizes and types of insulation that can be cut. Examples:

|

|||||||||||||

|

Tin Dipping – Most commonly used to fuse loose strands in preparation for soldering installation. Check out our blog post covering all the different types of tinning/tin dipping here. |

||||||||||||

|

Wire Dyeing/Re-Colouring Most wire is available in ten standard colour options to choose for their requirements. Sycor can dye white wire to any colour that you desire. The colour will not crack, run, or peel and is resistant to abrasion, corrosion, and fungus. Some wire and cable insulations are more susceptible to dyeing than others. Contact one of our sales representatives to help determine if a certain insulation material can be dyed.

|

|||||||||||||

|

Wire Striping Standard colour codes only give engineers 10 colour options. Striping wire allows various other colour code combinations to make working with large numbers of conductors more efficient. We can apply both Longitudinal (straight) and Spiral (twisted around) stripes. Our capabilities allow us to apply up to three stripes of three different colours per wire with 30% coverage as per the European (CE) specification. We can stripe various insulations and gauges. Most commonly striped insulations include PVC, SRPVC, XLPE, PVC + NYLON (TFFN/THHN) and XLPVC. More Information: APPLICATIONS

GAUGES AND SIZE LIMITATIONS We can stripe various insulations and gauges. Most commonly striped insulations include PVC, SRPVC, XLPE, PVC+NYLON (TFFN/THHN), AND XLPVC. We do not stripe Teflon or rubber in-house but can supply this type of material. Subject to put-up lengths and insulations. Our general capabilities are as follows. Contact our sales representatives to confirm your requirement:

|

|||||||||||||

|

Printing and Marking We specialize in custom marking and printing for customers who find it beneficial to have their trade name, part number, and/or logo on select wires, cables, tubing, and sleeving products. We can use both Ink Jet and print wheel systems to fully satisfy the needs of our customers. A one-time set-up fee applies to each printing setup. Wires/cables vary in diameter which affects what can be printed on the product. Contact one of our sales representatives for more information. Subject to certain minimums. You may also be interested in our custom cable product offering.

|

|||||||||||||

|

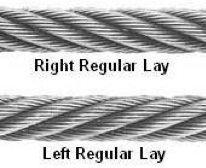

Twisting Twisting is commonly used in applications that require custom colour codes without the expense of using build-to-order cables. Twisting is used quite often with jumpers and cable harnesses to simplify cable installation and can reduce signal noise. The pattern repeats at certain intervals from 1/2” to 11/2” varying from gauge to gauge. The most commonly used lays are left-hand lays. More Information:

APPLICATION

GAUGES AND RESTRICTIONS

THE LAY OF A TWIST

|

|||||||||||||

|

Bonding We are one of the few manufacturers in North America that have the capability to bond wires together in a parallel construction. This is sometimes referred to as "festooning" and is used in jobs which require vertical flexibility due to space constraints. Conductors are bonded together using a specially formulated adhesive. More Information:

APPLICATIONS

MATERIAL WE CAN BOND

Single and Multi-Conductors Coaxial Cable Fiber Optics GAUGE & SIZE LIMITATIONS

22 to 24 awg – up to 18 conductors 18 to 20 awg – up to 18 conductors 10 to 14 awg- up to 8 conductors |

|||||||||||||

|

Bundling Quick Pull can save you time and money by eliminating the need of multi-spool setups. This service bundles wire and cable into a single-crossed, lashed cable assembly which allows for many wires to be pulled at once to simplify installation. With only one cable to pull, it will take less time to get the job done. Sycor can bundle any gauge wire, cable, and fiber optic type together with a strong bonded nylon material.

|

|||||||||||||

|

Terminating Do you need your wire or cable terminated or spliced? Beyond our capability to cut your product to length, we can speed up your production further by delivering your wire or cable ready to kit or install. We are tooled for most popular terminals and connectors and conform to UL and CSA standards. Let us know how we can help you.

|

|||||||||||||

|

Ground Straps For grounding where flexibility is required and an be made in various braid sizes. Ends can be tin-dipped and punched with a bolt hole, terminated with rings, or made into ground shunts with connectors.

|

||||||||||||

|

Custom Armouring Whether you have an indoor or outdoor requirement, adding a shielding of galvanized steel or aluminum to your core material can help control disruptions in data transmission. Sycor also has optional jacketing services. We can apply PVC to the outside of the armour to provide extra defence from dirt or water. This specially formulated PVC can be custom printed and comes in different colour options for better cable identification.

|

|||||||||||||

|

Tube and Sleeve Cutting Our automated state-of-the-art equipment allows us to keep cut tolerances accurate and eliminates costly mistakes incurred with hand cutting. Since many tubing and sleeving applications require custom lengths, Sycor provides custom cutting of all types of tubing and sleeving. More Information: APPLICATIONS

LIMITATIONS

|

|||||||||||||

|

Kitting and Labeling Let Sycor help you reduce production time! With our custom kitting service, we can prepare product kits for installations or pre-production. Our labelling service can help you with wire identification to speed up your production or make installations easier. Contact our sales team to see how we can serve you.

|

||||||||||||

|

Just-In-Time Blanket Delivery We encourage our customers to place a 6 or 12-month blanket purchase order to cover annual requirements. The materials are held exclusively for the customer and can be shipped with expedited delivery within one business day. This gives our customers great flexibility in scheduling their production. More Information: BENEFITS

DETAILS

|

High-Quality Guarantee from a Proud Canadian Wire and Cable Distributor

If you are looking to customize your wire and cable in Canada USA INTL– we are happy to offer our Value Added Services. Sycor has over 30 years of experience as a wire and cable distributor, and we guarantee the highest quality of our products. No matter what application or device you are working with – we will find the best solution just for you!

Place Your Order Today!

To order Value Added Services from Sycor Technology, simply Request for Quote online, email us or give us a call. Our sales representatives are happy to assist you from Monday to Friday, 8:00 am to 4:30 pm.