Mil-Spec: M16878/3 vs. M16878/4

Voltage Rating: M16878/3 vs. M16878/4

The M16878/3 and M16878/4 are two products that have a number of similarities, but what people often forget is that there are several differences that make these cables unique. The first notable difference to point out is the voltage levels and type of insulation.

M16878/3 = PVC - 3000 Volts

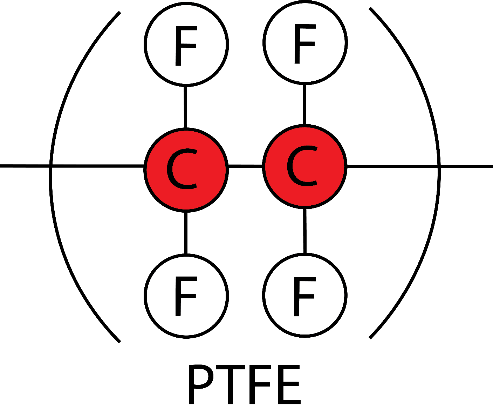

M16878/4 = PTFE - 600 Volts

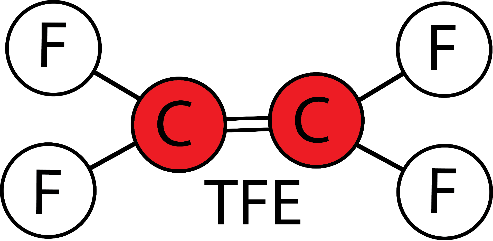

This is an important difference to note because although the 3000-volt design is meant for more demanding applications, PVC is one of the less expensive, weaker insulations that are available. On the other hand, PTFE is a very durable material that is well-known for being able to handle some of the toughest wire and cable applications, yet it only has to handle 600 volts. This is strange to see as you'd typically see the tougher insulation be paired with, the higher, more demanding voltage.

Temperature Rating: M16878/3 vs. M16878/4

The second important factor to take into consideration is the temperature rating, which highlights the hottest and coldest temperatures these cables are safely able to operate within. The temperature, similar to many other products, is based on the insulation thickness, material type, and overall voltage. The temperature rating for these cables is:

M16878/3 = 105ºC

M16878/4 = 200ºC

Conductor Differences

Another difference between these cable constructions lies in their conductors, specifically in the type of material. While the m16878/4 construction strictly uses tinned copper, the opposing m16878/3 has two available options (Silver and tinned). The two materials are part of the reason why the voltage rating is so much higher in "/3" construction.

|

+ |

Silver Conductor = |

|

|

+ |

Nickel Conductor = |

|

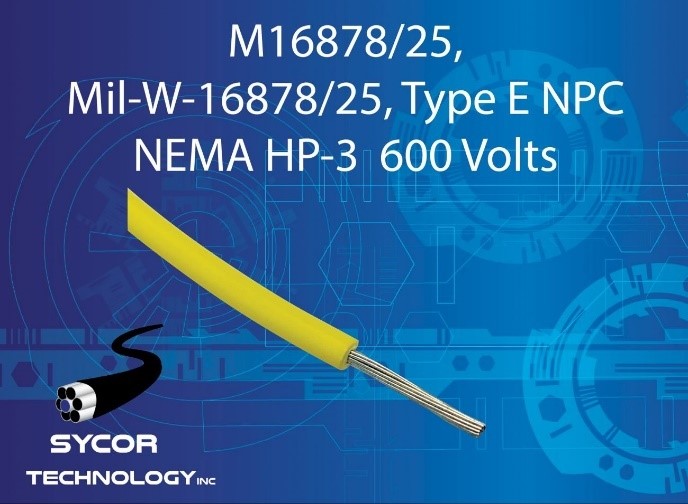

What's interesting to point out about the m16878/4 construction is that it also has an alternative conductor. The alternative conductor is made of nickel-plated copper and is slightly different than m16878/3's. The difference lies in the designation, because while the "/3" is able to change conductors and still be considered that same m16878 slant, when the "/4" changes conductors the construction turns into an entirely different product or "designation" (m16878"/25"). This believe it or not is moderately common between the different mil-spec wiring categories as the cables

The insulation type is an important point, but what is also important to note is the thickness of the insulation. The material type helps protect the inner conductors from harmful things like acid, oil, and water. The insulation thickness is created to withstand specific applications and the surrounding environment that resides within. This can be anything from simple sunlight, high-temperature environments, oil, water, weathering, abrasion, crush, and many more.

M16878/3 = 0.031"

M16878/4 = 0.010"

M16878/3 & M16878/4 Alternative Constructions

Similar to using the different conductors, these m16878 wires are also available in different certifications. Please note that with a different certification, these cables become non-mil-spec wire. The products specifically become CSA and/or UL rated products.

The different designations that these cables take on will entirely change the name of the cable, yet the construction stays the exact same. This is a little bit weird when you first learn about this, but it does make sense, and here's why. CSA stands for Canadian Standards Association, and it, along with Underwriters Laboratory (UL) were created in order to pass minimum safety requirements. These requirements also change based on the applications that fall under a specific designation.

M16878/3 = TEW UL1015 & UL1028 = REW UL1431

All of these underlined cable types above are the exact same construction, yet are used for entirely different applications.

- The M16878/3 is used for military applications and general cabling.

- The TEW UL1015 & UL1028 hook-up wire is typically used for machine tool wiring and for AWM applications involving computer or appliance wiring.

- REW UL1431 hook-up wire is generally used for motor leads or internal wiring of appliances.

If you were to click the links above and compare the similar gauge sizes, you'd notice that these cables are basically identical (except for voltage rating). From conductor type, insulation, and even the temperature rating, these cables are meant for different applications but are created with the exact same materials and dimesons.

- The M16878/4 is used for military and general applications that don't exceed 600 volts.

- CSA AWM UL1213 is typically used for internal wiring but is unable to be subject to abuse.

Both of these M16878 cable designations are very important for a number of industries worldwide, from highly detailed applications to simple, cost-effective applications not requiring any UL or CSA certifications. Overall the construction of the M16878/3 Type D and the M16878/4 Type E are very similar yet bring vastly different qualities to applications they are applied to. That concludes our mil-spec comparison. If you have any questions or concerns about the different mil-spec construction, feel free to reach out to one of our technical experts.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]