Portable cords may be used in commercial, residential, and industrial applications. These electrical cords are designed with a resistance to oil, chemicals, abrasion, heat, and cold for both inside and outside environments. Some of these cables have the ability to be water or weather-resistant and water-submersible. These types of cabling products are very reliable for applications involving mills, mines, sports complexes, or marinas.

The portable cords come in the standard extra hard service (600V) and junior service (300V). The next important aspect is the required temperature ratings because when it comes to the standard portable cords, there are three types to choose from. The first is the Thermoplastic Elastomer Jacket (TPE) portable cord that's rated for -50ºC to +105ºC. The second type of portable cord construction is the Thermoplastic Jacket with a -40ºC to +60ºC. The final standard portable cord and the most popular one, Thermoset Rubber (EPR) -40°C to +90°C.

Portable Cord Features

Sycor offers portable cords with:

- Multiple conductors

- Multiple configurations

- National & international standards

- Various shielding options

- Multiple NEMA plug options

- UL & CSA ratings

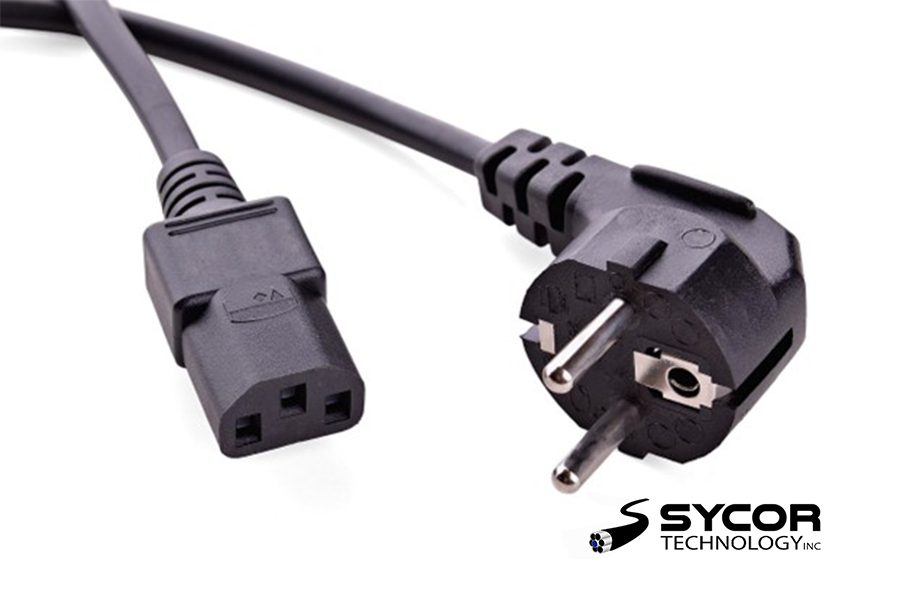

A portable cord (AKA portable cordage, flexible cord or extension cord) is an electrical multi-conductor that's used for temporary power connections that require flexibility. The portable cord can be installed into various applications, such as operating motors in small and large tools, equipment, power extensions, machinery and home appliances. The portable cords are offered in fewer AWG sizes than other traditional cables as they come in various conductor counts. With certain portables cords being able to carry up to 40 conductors, these electrical cables have the ability to meet the requirements for power transmission no matter how difficult.

|

Type |

AWG Range |

# of Conductors |

Insulation & Jacket |

Voltage |

|

SPT-1 |

18 |

2 or 3 |

PVC / No Jacket |

300V |

|

SPT-2 |

18-16 |

2 or 3 |

PVC / No Jacket |

300V |

|

SPT-3 |

18-10 |

2 or 3 |

PVC / No Jacket |

300V |

|

SPE-1 |

18 |

2 or 3 |

Elastomer / No Jacket |

300V |

|

SPE-2 |

18-16 |

2 or 3 |

Elastomer / No Jacket |

300V |

|

SPE-3 |

18-10 |

2 or 3 |

Elastomer / No Jacket |

300V |

|

SV |

18 |

2 or 3 |

Rubber / Rubber |

300V |

|

SVO |

18 |

2 or 3 |

Rubber / Rubber |

300V |

|

SVOO |

18 |

2 or 3 |

Rubber / Rubber |

300V |

|

SVT |

18 or 17 |

2 or 3 |

PVC / PVC |

300V |

|

SVTO |

18 or 17 |

2 or 3 |

PVC / PVC |

300V |

|

SVTOO |

18 or 17 |

2 or 3 |

PVC / PVC |

300V |

|

SVE |

18 or 17 |

2 or 3 |

Elastomer / Elastomer |

300V |

|

SVEO |

18 or 17 |

2 or 3 |

Elastomer / Elastomer |

300V |

|

SVEOO |

18 or 17 |

2 or 3 |

Elastomer / Elastomer |

300V |

|

SJ |

18-10 |

2, 3 or 4 |

Rubber / Rubber |

300V |

|

SJO |

18-10 |

2, 3 or 4 |

Rubber / Neoprene |

300V |

|

SJOO |

18-10 |

2, 3 or 4 |

PVC / PVC |

300V |

|

SJT |

18-10 |

2, 3 or 4 |

PVC / PVC |

300V |

|

SJTO |

18-10 |

2, 3 or 4 |

PVC / PVC |

300V |

|

SJTOO |

18-10 |

2, 3 or 4 |

PVC / PVC |

300V |

|

SJTW |

18-14 |

2, 3 or 4 |

PVC / PVC |

300V |

|

SJE |

18-10 |

2, 3, 4 or 5 |

Elastomer / Elastomer |

300V |

|

SJWO |

18-10 |

2, 3, 4 or 5 |

Elastomer / Elastomer |

300V |

|

SJEOW |

18-10 |

2, 3, 4 or 5 |

Elastomer / Elastomer |

300V |

|

SJEOO |

18-10 |

2, 3, 4 or 5 |

Elastomer / Elastomer |

300V |

|

S |

18-2 |

2 or more |

Rubber / Rubber |

600V |

|

SO |

18-2 |

2 or more |

Rubber / Neoprene |

600V |

|

SOO |

18-2 |

2 or more |

Rubber / Neoprene |

600V |

|

ST |

18-2 |

2 or more |

PVC / PVC |

600V |

|

STW |

18-2 |

2 or more |

PVC / PVC |

600V |

|

STO |

18-2 |

2 or more |

PVC / PVC |

600V |

|

SE |

18-2 |

2 or more |

Elastomer / Elastomer |

600V |

|

SEO |

18-2 |

2 or more |

Elastomer / Elastomer |

600V |

|

SEOW |

18-2 |

2 or more |

Elastomer / Elastomer |

600V |

|

SEOO |

18-2 |

2 or more |

Elastomer / Elastomer |

600V |

|

HPN |

18-12 |

2 or 3 |

Neoprene / No Jacket |

300V |

|

HSJ |

18-12 |

2, 3 or 4 |

Neoprene / Rubber |

300V |

|

HSJO |

18-12 |

2, 3 or 4 |

Neoprene / Neoprene |

300V |

|

HS |

14-12 |

2, 3 or 4 |

Neoprene / Rubber |

300V |

|

HSO |

14-12 |

2, 3 or 4 |

Neoprene / Neoprene |

300V |

Additional Services

|

S |

Service Grade (also means extra hard service when not followed by J, V, or P) |

|

J |

Hard Service |

|

V |

Vacuum cleaner cord (also light-duty cable) |

|

P |

Parallel cord (also known as zip cord) – Always light-duty |

|

E |

Thermoplastic Elastomer (UL/NEC designation ONLY) |

|

O |

Oil Resistant* |

|

T |

Thermoplastic |

|

W |

Outdoor-rated sunlight resistant jacket and wet location-rated conductors (formerly “W-A”) |

|

VW-1 |

Flame retardant (Vertical specimen Flame Test) |

|

FT2 |

Flame retardant (Horizontal specimen Flame Test) |

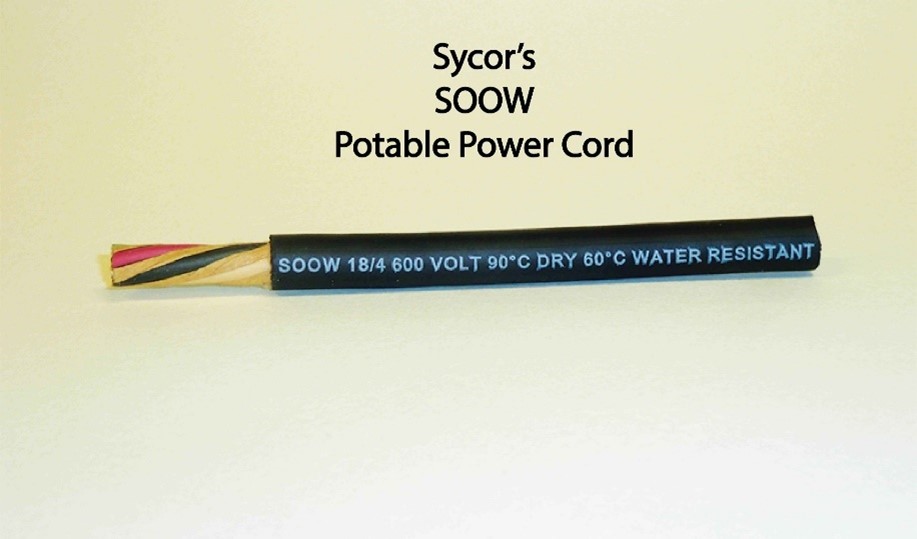

Type SOOW |

Type STOW |

Type SEOOW |

|

S for Service OO for Oil-resistant insulation and Oil-resistant jacket W for Weather and Water resistance. Rated to: 600 Volts |

S for Service T for Thermoplastic O for Oil-resistant jacket W for Weather and Water resistance Rated to: 600 Volts |

S for Service E for Thermoplastic Elastomer OO for Oil-resistant insulation and Oil-resistant jacket W for Weather and Water resistance. Rated to: 600 Volts |

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]