Evolution of Wire Lighting

With the evolution of electricity in the late 18th century, by Thomas Alva Edison, lighting quickly switched to wire and cable lighting fixtures. This was basically the lighting revolution, as the next century quickly saw wire and cable lighting prevalent in buildings, cars, planes, boats, and thousands more unbelievable inventions.

Wire and cable lighting today is the same concept it was with Edison, which is transferring a controlled flow of electricity from a power source through a wire or cable, to a specific lighting fixture. Over the years, different technologies have been adapted (energy-conscious designs), that have overall made lighting more readily available.

From discovering fire thousands of years ago to producing so much light around the world that you can see it from the space station. As wiring has evolved over the years, so has the lighting fixtures it supplies, and only because of these simultaneous changes are societies around the world able to produce and supply as much light as they do today.

Popular Lighting Wire and Cable

Lighting Wire: Power Cord’s

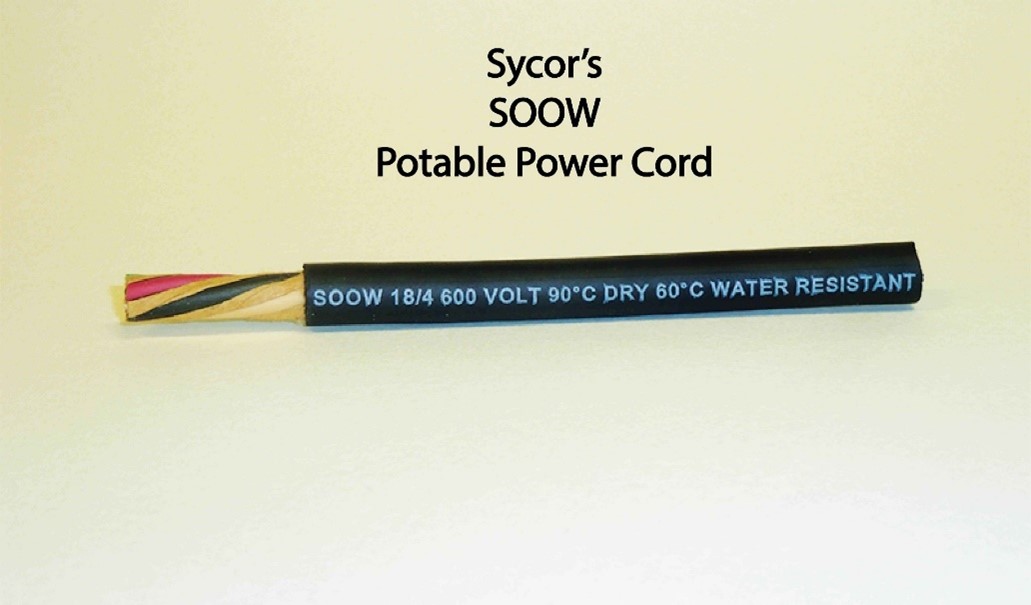

Some of the most popular types of lighting wire available are the different types of power cords. Power cords can be used in overhead, exposed, or even in direct-burial applications. They're a popular choice for applications in the electric utility, industrial, and commercial markets.

Portable & Power Cord Breakdown

- S = Extra hard service (rated for 600V)

- J = Junior (hard) service (rated for 300V)

- V = Vacuum cord (rated for 300V)

- P = Parallel cord

- E = Elastomer jacket (UL or NEC only)

- T = Thermoplastic jacket

- O = Oil resistant outer jacket

- OO = Oil-resistant outer jacket and inner insulation

- W = Weather and water-resistant - outdoor rated (note: this is NOT the same as Type W, another kind of portable cord)

Being most popular in the SOOW and SOW (SOW-A) constructions. The list above highlights what each letter means in the different types of power cord constructions. With lighting being essential in every single market, the different power cord constructions allow for more variety when selecting a specific wiring solution.

Lighting Wire: Hook-Up Wire & Building Wire

Hook-up wire and building wire are 2 more popular wiring categories that have several different types of approvals and wiring constructions.

|

TEW - Tinned or Bare Copper |

UL TFFN Wire |

|

TR64 - UL1007, UL1569, UL1581 |

T90 Wire or UL THHN |

|

REW Wire UL1431 |

|

|

CL1251 - UL3173, UL3195, UL3196 |

Hook-up and building wires are more general-purpose wires that are perfect for cost-effective solutions, for applications that aren't subject to harsh environments. Being general-purpose wiring allows these cables to be used in a much more extensive selection of applications in a number of different markets.

Lighting Wire Terminations

Lighting wire can have a number of different constructions depending on what your application demands. Be it the simplest application or the most difficult; lighting wire has 1 consistency, which is Ring Terminals. Ring terminals are the most popular type of way to connect a power source to a lighting fixture. Ring terminals are quick and cost-effective terminations that make most applications extremely efficient during setup and maintenance.

Types of Ring Terminals

- Non-Insulated Ring Terminals

- Vinyl Ring Terminals

- Nylon Ring Terminals

- Heat-Shrink Ring Terminals

- High-Temperature Ring Terminals

|

|

Colour Codes of Lighting Wire

Similar to other applications, when dealing with lighting wire and cable, several NEC requirements must be followed as a type of safety regulation.

|

Function |

Label |

Colour, Common |

|

Positive Ground |

PG |

Green or Green/Yellow |

|

Neutral |

N |

White |

|

Line, Single Phase |

L |

Black or Red (2nd hot) |

|

Line, 3-Phase |

L1 |

Red |

|

Line, 3-Phase |

L2 |

Black |

|

Line, 3-Phase |

L3 |

Blue |

Sycor distributes extremely durable stage lighting cables that are designed to withstand severe environmental conditions. Our stage lighting cables are not only water and sunlight-resistant, but they're also able to withstand exposure to oils, alkalis, acids, heat, flames, moisture, and chemicals as well. The stage lighting cables we distribute are available in an array of sizes and conductor configurations, making Sycor Technology the place to go for all your specialty lighting needs.

Lighting wire and cable come in a number of different constructions and can be used in vastly different applications in a number of markets. If you have any questions about which high-temperature wire your application calls for, feel free to reach out to one of our wiring experts for any help you may need.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]