How do different temperatures affect a cable's performance?

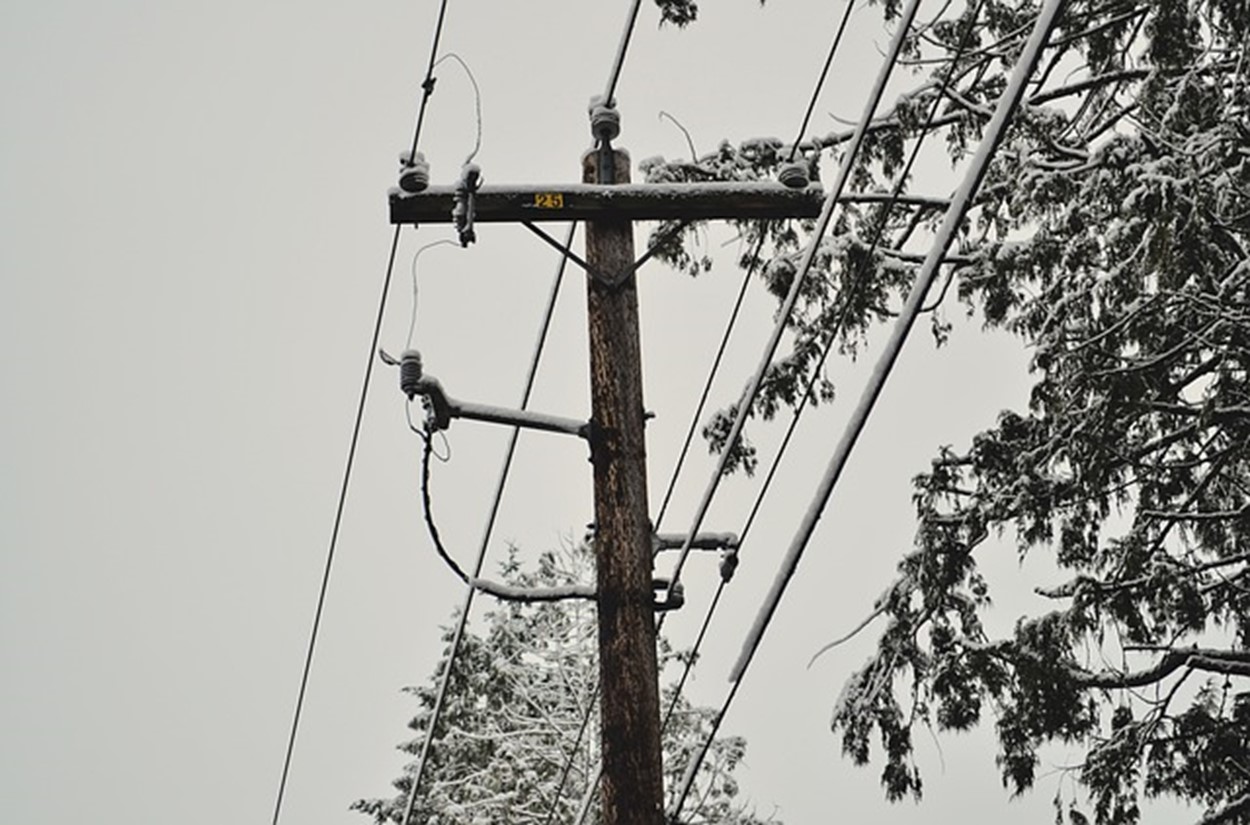

A consistent issue with extremely cold environments is the power going out (Brownout / Blackout). This typically occurs when large numbers of people are using high levels of energy. These temporary power outages often happen on cold days, specifically in neighborhoods with older houses, because of the older, more energy-intensive systems. These types of heaters require massive amounts of energy to heat a home compared to more developed systems. When many households connected through the same power lines begin drawing large quantities of power simultaneously, the power lines and the associated transformers may have trouble keeping up with the demand.

Another cause of this issue is the cold itself. Whether it's boiling hot or freezing cold, the internal components will be slightly less efficient than if the internal components were operating in an optimal setting. Recent technological improvements may be able to perform more effectively in extreme temperatures, but regardless, those moving electrical components will need to work just a little harder to achieve the same result as they would on a more favourable day.

Why temperature is an important consideration for electrical applications

Extreme temperatures, cold or hot, can have adverse effects on your wire and cable, which can cause the product to become brittle and inflexible. When cables are installed in conditions they aren't suited for, the cables will stiffen and crack with freezing temperatures. In order to combat the freezing temperatures, wire and cable with sufficient cold temperature ratings are required. See the wire and cable material breakdown below.

Temperature Ratings for Electrical Materials

Conductor/Shield Wire:

- Silver Plated Copper = 200°C - 250°C

- Nickel-Plated Copper = 250°C (27% Nickel 450°C - 550°C)

- Stainless Steel = 250°C

Extruded Insulation/Jacket:

- Fluoropolymer (PFA, FEP, ECA, ETFE) – Fluoropolymers retain properties over a range of temperatures. PFA is acceptable for use from -200°C to 250°C, and ECA is acceptable for use up to 300°C.

- Polyester – Like Fluoropolymers, Polyesters are not very flexible, so used for primary insulation and thin jackets. Retains properties down to -100°C and below.

- TPE – Has excellent retention of flexibility at low temperatures. TPE has been used successfully in temperatures as low as -100°C.

- Silicone Rubber – Most silicone grades are acceptable for -75°C to 150C, but specific grades can extend down to -90°C or up to 250°C.

Tapes:

- Polyimide – General grades are suitable for 350°C

- PTFE – 250°C

- Mica-mat – +600°C

- Woven Fiberglass – E-glass to 250°C, S-glass to 450°C

Fillers/Textiles:

- PTFE/PFA Monofilament – 260°C

- Fiberglass – E-glass to 260°C, S-glass to 450°C

- Aramid – 160°C

Industry Standards: Temperature Ratings

The different industry safety standards that have been refined over the years have enabled highly resistant wire and cable products to be used in extremely demanding application environments. Cold bend testing is one of the more common UL standards, while the cold impact test is another popular test and is used to determine if a cable can be marked with a lower temperature rating. CSA is a little bit different as the legal standards may vary from the ULs, the cold bend and cold impact tests. It is vital to check every industry's application as each job has a different set of safety standards that must be met.

Wire and cable applications have several essential considerations in order for the application to be completed successfully and safely. Various institutions have come up with different standards for specific geographic areas that have been consistently refined over the years, enabling wire and cable applications to be safely and cost-effectively completed. With new developments always around the corner, ratings like the CSA FT1 - FT6 ratings, ROHS, UL VW-1, and CE have set the standards for completing wire and cable applications.

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]