The Do's & Don'ts of Wire Cutting and Stripping

Providing a service is the action of accomplishing specific tasks for a set fee, which will often provide a higher ROI than the alternative. In other terms, outsourcing part of the operation will help save time, labour, organization, and investment costs. Wire cutting is one of these services, and as we compare smaller and larger-scale operations, you'll begin to notice different opportunities that start to emerge.

Wire Cutting & Stripping Styles!

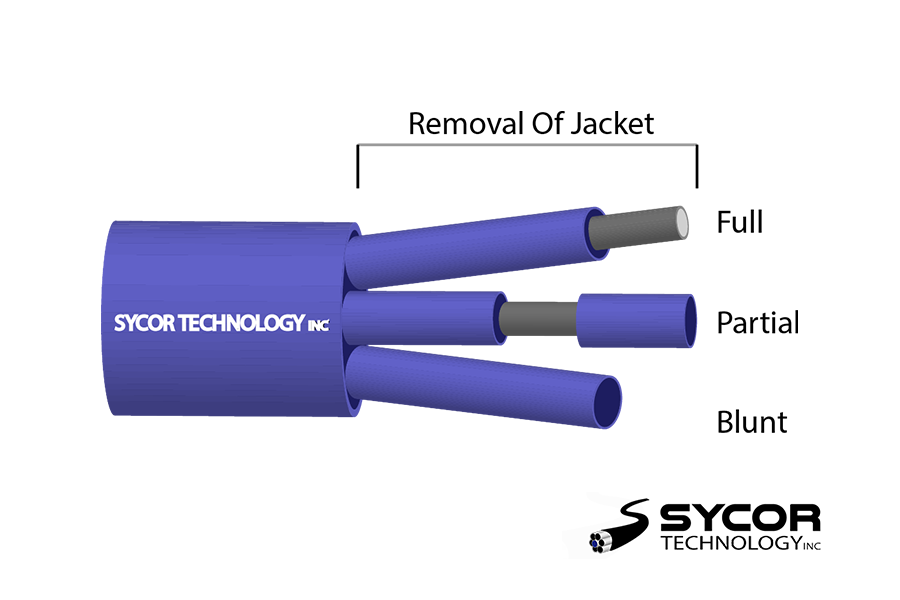

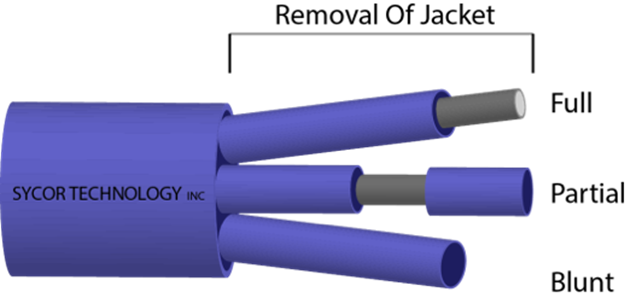

When it comes to cutting wire and cable, there are three standard techniques. These techniques differentiate by type of jacket removal and provide various benefits to its intended application.

Full: A full cut and strip is when the insulation is removed, exposing the conductors at the desired length. This method involves cutting and physically removing the insulation and jacket to expose the conductor in the middle. This technique is typically used when our team is also requested to crimp or solder accompanying terminations.

Partial: The Partial Strip is the middle ground between the blunt and full strip techniques. A partial strip is when the end piece of the electrical wire or cable is cut to the desired length and has the cut insulation left on. This technique does a few things:

- It cuts the cable to its desired length.

- Leaving the jacket on the insulation helps protect the inner conductor from any outside abuse.

- Lastly, protecting the inner components also makes setup time and terminations significantly faster.

Blunt: The blunt cutting and stipping style is, in reality, just the cutting aspect. The blunt style merely cuts the cable to its desired length. This technique is the most simple and can significantly save your team time and labour if appropriately applied.

- Blunt cuts are very different than the other two types of cutting as they only involve the process of cutting. By leaving the end attached and uncut, enables the end-user to strip to their desired lengths but will inevitably increase the setup time and labour.

Combining Value-Added Services

A common trend our team has mentioned throughout the years is our customers will often combine a few different value-added services in order to have the most cost-effective outcome. Our cable assembly team typically notices terminating requests that will follow cut and strip orders. Terminations can take an extensive amount of time, so by combining more than one service, we're able to complete your labour with increased efficiency and reduced labour cost. This means that when the products arrive on-site, they'll be 100% ready for installation, with little to no prior setup.

Different Methods for Cutting & Stripping

For the last portion of this blog, we'll be showing the two most prevalent types of cutting. This portion is important to note because it helps break down the two main methods that customers have access to, which are cutting machines or cutting by hand. Each has various benefits that differentiate based on the application and planning beforehand.

Cutting & Stripping By Hand

|

|

The first and most popular way to cut wire and cable is by hand. Hand Strippers are the most common way for our customers to cut their cables, as it is affordable, reliable, and allow for additional customization if required. Hand stripping, just like other methods, has pros and cons that it brings to its intended applications.

5 Steps to Cut & Strip Your Wire By Hand 1. Determine the wire gauge and type: The first step in the hand-cutting process involves identifying the gauge. The gauge is important to note because when stripping the wire by hand, you'll need to penetrate the external sheathing without breaking the inner conducting metal.

2. Match the wire to the tool: This is an essential step in the process because matching the wire up with the correct-sized hole will ultimately determine if the cut is "clean." For example, If you choose an AWG that's too small, then you may end up cutting the conductor, and if you end up picking a one that's too big, then you'll have a much harder time trying to remove the outer insulation/jacketing.

3. Open the tool and seat the wire: This step involves placing the wire in the correct hole and pressing it down until you can't go any farther. This action will penetrate the insulation the perfect amount, which will then allow the material to slide easily off.

4. Twist (optional): The next step is optional, as it isn't always required. Sometimes the insulation won't cut clean through, which is why twisting is the next step. Twisting around the penetrated insulation allows a finishing cut for smaller uncut pieces.

5. Strip the insulation: The final step is to pull the insulation off of the cable. This action is just like taking off a sock. Simply grab both sides and slowly remove the insulation. If you're having difficulties with this step, then you more than likely need to use a small gauge size. |

Automated Wire Cutting Machines

|

|

Wire Cutting & Stripping Machines

The electrical wire cutting machines are by far the most effective although, they can be replaced. The different cutting machines are the most cost effective method, but only when it comes to large quantities of the same type of cuts. A common misconception about this method of cutting is most machines have the ability to cut and strip all sizes of cabling products when in reality most of these machines are only designed for a specific range of gauge sizes (Standard: 8 AWG to 22 AWG). These machines fluctuate in price based on brand, but one common consistency across brands is that automated cutting and stripping for large quantities of cable is significantly more cost-effective than if it were to be completed by hand.

The most popular type of machine out right now is the Astro construction. The Schleuniger wire-cutting machine is the smaller image on the left and is typically used for smaller gauge sizes. Being able to cut thousands of pieces of wire an hour, without breaks and without human error, makes this tremendously more cost-effective in large quantities. The only time machines such as these are rendered less effective is when the entire application isn't 100% known. This means specific applications may not have prior measurements, and rather than going on-site to check, it's often easier to cut the exact amount required while working on-site.

Cut & Strip Summary

Wire cutting and stripping have become one of the most relied-on electrical services in the last few decades. From simple applications to large manufacturing operations, every application is unique and can have various ways to increase its efficiency and its overall cost-effectiveness. Whether your application requires a full cut, partial cut, or a blunt cut, our team has the tools at our disposal to make your application significantly less stressful, as well as help, provide a high-quality end result. For more information on our cutting service feel free to reach out, and one of our industry experts will help you out ([email protected]).

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]