Sycor's Different Terminations

What is a Wiring Termination?

A wire termination is a piece of electrical equipment that's attached to either end of an electrical wire. This unique piece of electrical equipment is used to connect two or more electrical devices (switch, terminal, or connector). There are many different types of terminations, but the majority of them will fall under one of the two popular construction types. Before we get into the different types of terminations, we'll first break down the two main methods of terminating. These are important to note as most of the terminations fall under one of these or both.

Solder Termination

Soldering was first invented around 3,000 BC, although the applications involved more basic metal soldering, as electrical equipment never existed. A solder termination is when the open connector is melted and sealed to create an extremely strong bond, overall forming a permanent connection. Before installation, the desired wire or cable must first have the end of the insulation removed, and Flux applied before finally connecting the solder termination. Some types of Flux also require periodic maintenance as certain ones may damage surfaces or the connection over time (this is only for specific constructions). The solder termination is also used traditionally less, as the constructions are more time exhausting, than the crimp alternative.

The J-STD-001 also provides specific instructions for installing these types of terminations (Requirements for Soldered Electrical and Electronic Assemblies). Being a popular type of termination in the world of wire and cable today is also why it's often recommended as a more reliable alternative for crimp terminations. Safety is another important factor to keep in mind, as hot irons and molten metal aren't the safest materials to be handling. That is why we provide our cable assembly and wire harnessing team with extensive training and testing before we allow individuals to work with these potentially dangerous materials.

Crimp Termination

A crimp termination is the most commonly used type of termination and is utilized when a specific appliance or device requires direct contact with the cable. The "crimp" forms a powerful connection and is attached by using a crimp tool with specific connectors. The crimp termination is heavily used in aircraft wire harnesses, circuit breaker panels, and specific aircraft such as F-15, C-130, UH-60, and many more.

Automation: Crimp Termination

Crimping a termination can also be automated based on how many different terminations are required. For low-volume work, electrical workers will typically work with a number of handheld crimping devices, as it's often a much more cost-effective method for low-volume orders. In general, every termination is important, but the quality of termination may also be determined by the application. What this means is that if we are terminating a lighting fixture compared to a heart pacemaker, the degree of quality will be increasingly more precise for a pacemaker. The degree of quality is an essential part of every assembly and will always abide by the specific assembly regulations. Lastly, there are specific applications that require the crimp termination to be soldered as well. This is done to accomplish one of 2 things: corrosion resistance or for additional strength and reliability in critical applications (aerospace). With applications like aerospace, failure isn't an option, which I why precise regulations have been set in place, so the safety of the general public and the electrical personnel are never at risk.

Crimp vs. Solder Terminations |

||

|

Crimp Termination |

Solder Termination |

|

|

Easy process control |

Yes |

No |

|

Suited for high production level |

Yes |

No |

|

Suited for low production levels |

Yes |

Yes |

|

Low operator learning curve |

Yes |

No |

|

Heavy metal (e.g. Lead) exposure |

No |

Yes |

|

Low initial setup cost |

No |

Yes |

Popular Types of Terminations

O-Ring Terminations (Ring Terminals)

Ring terminals are the most popular type of way to connect a power source to a lighting fixture. Ring terminals are quick and cost-effective terminations that make most applications extremely efficient during setup and maintenance. This is one of the more simple types of terminations, which makes it ideal for more basic applications, such as lighting fixtures and appliance wiring.

Types of Ring Terminals

- Non-Insulated Ring Terminals

- Vinyl Ring Terminals

- Nylon Ring Terminals

- Heat-Shrink Ring Terminals

- High-Temperature Ring Terminals

Power Cable Terminations

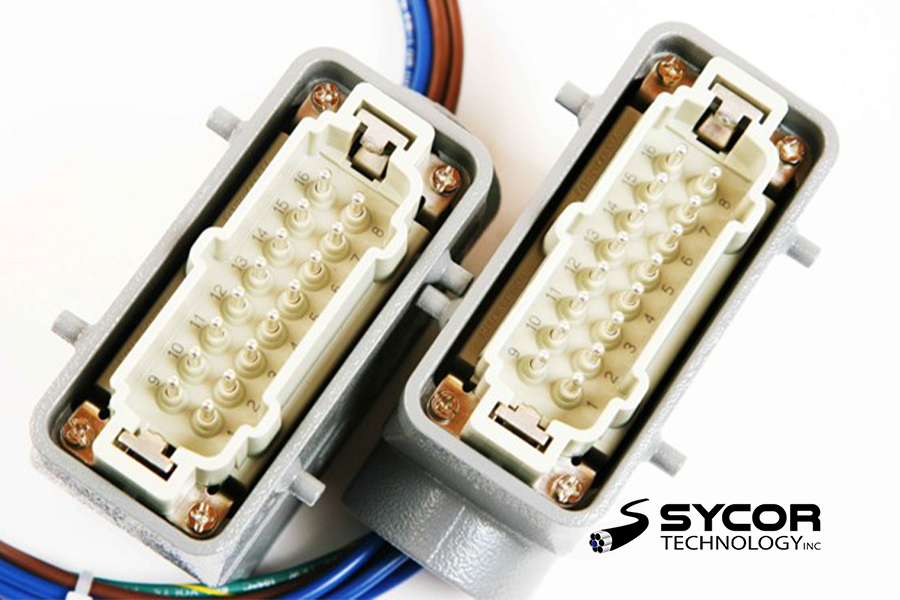

Power cables can range from low to high-voltage ratings. The medium voltage cables typically use a power shovel feeder for plugging into applications like welding receptacles. This is a very common type of connector and is often the one used within basic appliances and less critical applications. The other low voltage multi-conductor and control instrumentation applications typically use pin and sleeve type terminations, which are also very commonly requested products.

The Pin and Sleeve constructions are high-quality, secure connections that are used because of their ability to handle abuse if harsh application environments. These connections are best known for being used in applications like welders, motor generators, compressors, portable lighting fixtures, portable power tools, and conveyors. Overall, this wiring termination is a strong alternative in custom cable assemblies and wire harness applications, but also one that's not nearly as common.

Wire and cable terminations are an extremely important part of a variety of different industries, and even when it's not physically being inserted into the product itself, they're often utilized in the manufacturing of the product. Our cable assembly team has been conducting business since 1981, along with our technical sales specialists who've helped create some extremely complex assemblies. If you're still curious about the different types of terminations we offer, feel free to reach out, and one of our sales experts will help break down the best options and some alternatives for your application. Hope this was helpful!

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]