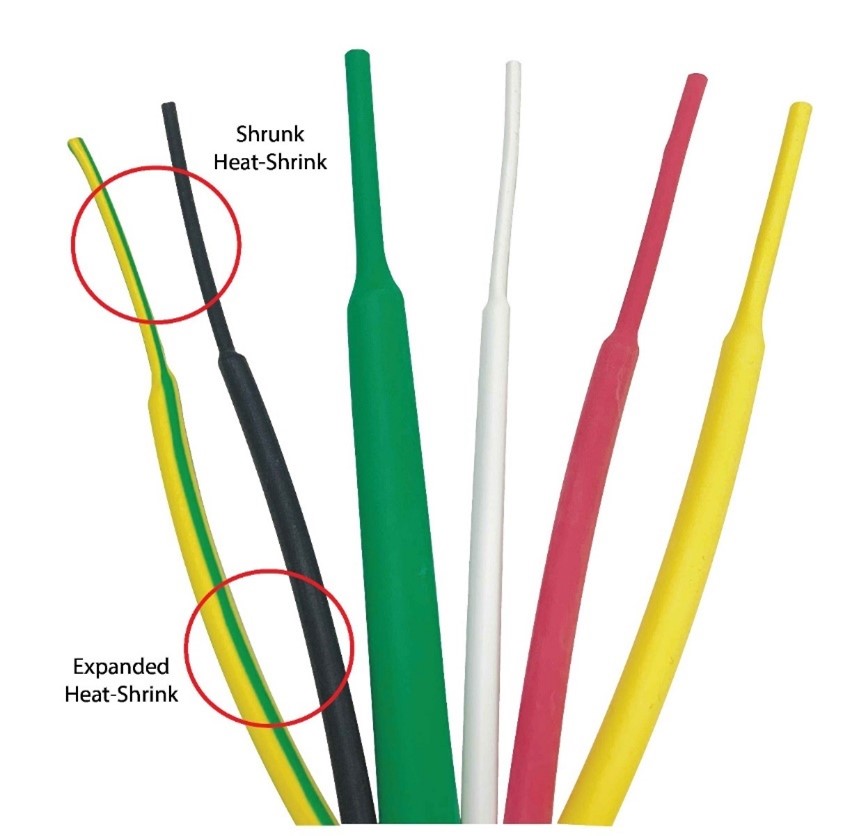

Shrink Ratios

4:1 = 25% of original form

3:1 = 33% of original form

2:1 = 50% of original form

Heat Shrink Wall Thickness

Heat Shrink for most distributors comes in one set construction that's available in various sizes. Sycor's heat shrink tubing capabilities slightly differentiates from this norm, as our team stocks up to four standard wall thickness for specific materials. The various heat shrink wall thickness are important for two reasons:

- The insulation thickness determines how much voltage a single wire can handle. The thicker the insulation, the higher the voltage level the heat shrink can handle.

- The different wall thicknesses are also a major consideration in applications that require limited space.

The different levels of wall thickness availability are determined by the type of product being used, the material type, and the manufacturer. Some of the different wall thickness available at Sycor are:

- Heavy Wall

- Standard Wall

- Light Wall

- Thin wall

Types of Heat Shrink

Adhesive-lined Heat Shrink

The dual-wall adhesive-lined heat shrink tubing is unlike any other cable management product. Once the heat is applied to the heat shrink's adhesive line (the polyolefin), melts to its intended source, ensuring a tight fit. The adhesive-lined heat shrink is also typically supplied in strips rather than the standard rolls. This is done to stop the adhesive from accidentally melting into the spool, which can happen from being in a high-temperature environment.

Dual Wall Heat Shrink

Dual wall heat shrink is built with an external layer of PTFE and an internal layer of FEP for double the resistance. PTFE/FEP dual wall heat shrink provides moisture, chemical and corrosion resistance while being reliable in high-temperature environments. This is a unique product that is only available through specific distributors and manufacturers. This insulation is not cheap and isn't available on a spool. This type of construction is packaged together in 4-foot lengths.

Questions to ask yourself before Ordering Heat Shrink:

- What’s the minimum inside diameter you need your non-shrunk heat shrink to be?

- Make sure your cables can fit in the non-shrunk heat shrink.

- What shrink ratio do you need?

- This question's important because it determines how tight your heat shrink will be. You should keep your application in mind because certain applications excel with different ratios of shrinking. For example, connectors should typically have a high shrink ratio, because it makes the overall connection more secure.

- What is the minimum length required?

- When heat is applied, the tubing loses a small portion of its overall length.

- What do you need the finished wall thickness to be?

- This is the final important question because when anything expands, it gets thinner, and the opposite occurs when things shrink. This last question is typically vital if the wall thickness is an essential part of the application.

Heat shrink is often an overlooked cabling product that's not only one of the most popular but one of the most reliable. Being available in various material types, shrink ratios, and wall thicknesses have enabled heat shrink to become a reliable solution for applications in just about every industry. With resistances against chemicals, oil, flame, abrasion, water, weather and even alkali, Sycor has heat shrink constructions that are able to stand up to even the most demanding electrical applications. Whether your building a cable assembly, need an additional layer of insulation or simply are trying to organize your cables at home, Sycor has the Heat shrink construction to make your heat shrink application a reality.

Popular Heat Shrink Constructions:

For more information about us:

Call Toll Free - 1.800.268.9444 or Email Us - [email protected]